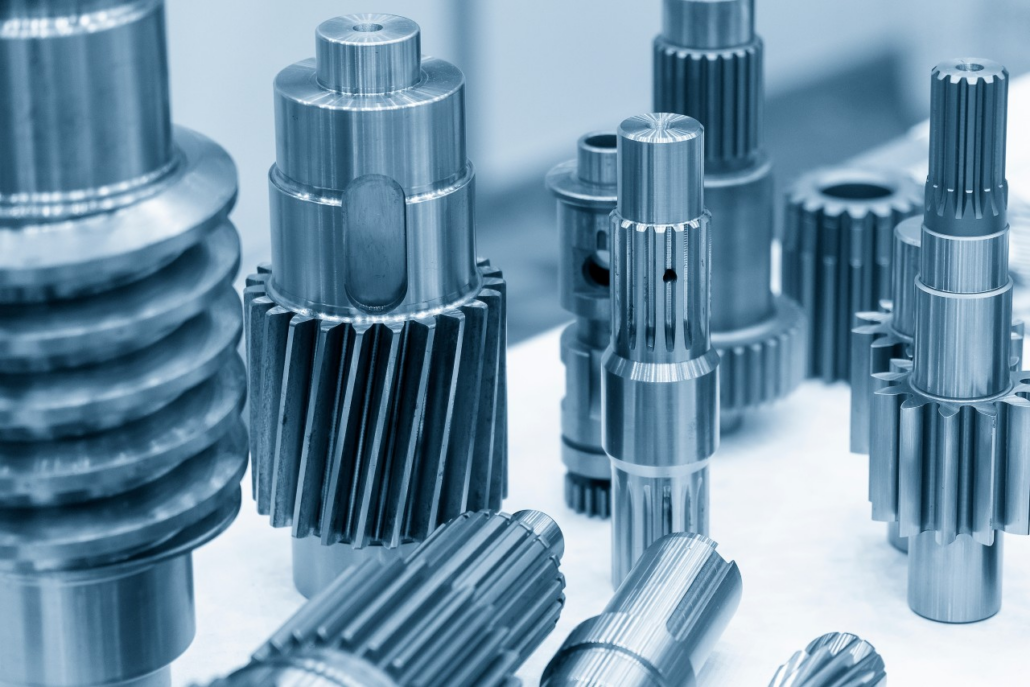

Splined Shafts: Features and Applications

Everything you need to know about splined shafts, essential components for efficient and secure power transmission

Splined shafts are crucial components in mechanical transmission systems and are used in a wide range of industrial sectors, from automotive to aerospace, heavy industry to robotics. These mechanical elements are designed to transmit torque and power efficiently, ensuring a secure coupling between transmission elements such as gears, pulleys, and joints.

Unlike traditional cylindrical shafts, splined shafts have a series of longitudinal grooves along their surface that allow precise coupling with complementary components, improving torsional resistance and reducing the risk of slippage. This makes them particularly suitable for applications requiring high load capacity and continuous, secure motion transmission.

Let’s take a closer look at what splined shafts are, their main features, materials used, and typical applications.

What Are Splined Shafts?

Splined shafts are components used to transmit power and motion between two mechanical elements, such as an engine shaft and a hub or gear. They are characterized by grooves on their external or internal surface, which fit with matching parts.

They can be categorized into several types based on shape and function:

- Parallel-spline shafts: designed for applications requiring uniform torque transmission;

- Helical-spline shafts: ideal for reducing noise and vibrations during operation;

- DIN and UNI spline shafts: manufactured according to international standards to ensure universal compatibility;

- Custom spline shafts: tailored to meet specific needs in sectors such as energy, automotive, and agriculture.

Materials Used in Splined Shafts

To meet the needs of various industries, splined shafts are made from carefully selected materials, including:

- Steel: the most commonly used material due to its strength, hardness, and ability to support high loads. Steel variants may include carbon steel, alloy steel, or stainless steel depending on specific requirements.

- Aluminum alloys: offer lightness and flexibility, making them ideal where weight reduction is crucial, such as in aerospace.

- Bronze: used in applications where minimal wear and quiet operation are critical, such as in precision gears.

- Titanium: known for outstanding mechanical and corrosion resistance combined with low density, ideal for high-performance, lightweight applications.

Material selection depends on operating conditions, environment, and the specific application of the shaft. Often, thermal treatments such as nitriding or case hardening are applied to enhance hardness and strength.

Characteristics of Splined Shafts

Splined shafts have uniformly distributed longitudinal grooves around the shaft axis, enabling coupling with hubs, gears, joints, or pulleys to transmit torque without slippage and with perfect synchronization.

An essential aspect of design is the geometry of the splines, which varies depending on the application:

- Straight splines: for standard applications with linear or rotary motion;

- Involute splines: for even load distribution and higher fatigue resistance;

- Helical splines: designed to improve torque transmission in dynamic systems.

Another key feature is dimensional precision and tight tolerances, achieved through advanced CNC machining and metrology controls, ensuring a perfect fit with other transmission components.

Customization of geometry, dimensions, materials, and surface treatments allows these components to be tailored to the specific needs of each industrial sector.

Ingranaggi Gandini offers custom solutions with splines in various shapes, ground or special profiles, and optimized features for every application. This design flexibility ensures compatibility with existing machinery, improves performance, and extends component life.

Production and Processing Methods

Manufacturing splined shafts requires advanced technologies and high technical expertise to ensure precision and reliability. Main production phases include:

- Turning: initial shaping of the raw material;

- Groove milling: grooves are created with milling machines and gear shapers according to specifications;

- Grinding: finishing process for optimal dimensional accuracy and smooth surfaces;

- Heat treatment: processes such as hardening and case hardening to increase wear resistance;

- Quality control: each shaft undergoes rigorous checks to verify compliance with dimensional and performance standards.

These steps, combined with cutting-edge machinery, ensure splined shafts meet the most demanding requirements for efficiency and longevity.

Applications of Splined Shafts

Splined shafts are used across various industries. Key applications include:

- Automotive: in transmission and differential systems to transfer power from the engine to the wheels, particularly in drive shafts and gearboxes.

- Industrial and mechanical sectors: in speed reducers and machine tools to transmit motion efficiently, enhancing energy performance and operational precision. Also used in automated handling systems like roller conveyors and robots.

- Agriculture and construction: in tractors, combine harvesters, excavators, and other site machinery, for transmitting power to tools like hydraulic pumps, PTO shafts, and gearboxes.

- Robotics and automation: in drive systems of industrial robots and mechanical arms, where they ensure smooth, synchronized motion, essential for high-precision applications.

Thanks to their versatility and customizability, they are suitable for compact, high-performance systems supporting the latest automation technologies.

Ingranaggi Gandini: Your Ideal Partner for Splined Shaft Manufacturing

Ingranaggi Gandini specializes in industrial gear production, including mechanical components such as splined shafts, delivering high-quality solutions for a broad range of industrial applications.

Our products include:

- Ground splined shafts: ideal for applications demanding maximum precision and reliability;

- DIN 5480, DIN 5482, UNI 220, UNI 221 profiles: manufactured to international standards for optimal compatibility and performance;

- Custom solutions: we collaborate with clients to develop tailor-made splined shafts to meet specific application requirements.

Want to learn more? Contact us today!