Gear Production: The Impact of New Technologies on the Sector

Numerically Controlled Machines and Robotic Automation to Optimize Precision Gear Processing

Gear production is a fundamental process for many industrial sectors, from automotive and robotics to precision machine tools. Gears are indeed essential components in motion transmission systems, as they allow for the transformation and modulation of power with high efficiency, minimizing energy losses. Their precision and durability can directly affect the performance of industrial machinery, vehicles, and advanced technological devices.

In recent years, the evolution of production technologies has revolutionized the sector with the introduction of innovative processes and machinery, such as numerically controlled machines (CNC) and robotic automation, as well as the use of advanced high-performance materials. Today, gear production is a constantly evolving sector that must be ready to meet the demands of a market increasingly focused on precision, efficiency, and reliability.

Let’s take a closer look at how gears are made and which new technologies are revolutionizing the sector.

How Mechanical Gears Are Made

The production of mechanical gears is a complex process that requires precision, technical expertise, and the use of advanced machinery. The process starts with the selection of the material, which varies depending on the final application: alloy steels, carbon steels, cast iron, or special materials are selected based on factors such as wear resistance, surface hardness, and operating conditions.

The first stage of the production process is forging or casting the raw material to create the initial piece, which roughly takes the shape of the gear. This is followed by a rough machining phase, usually performed using numerically controlled machines or machining centers, to achieve the basic dimensions of the component.

Next, the gear teeth are created through various machining processes, such as milling, slotting, or broaching. The final grinding phase, especially used for high-precision gears, ensures and enhances the precision and quietness of the gear. After the teeth are cut, gears may undergo heat treatments such as carburizing, hardening, or nitriding to increase surface hardness and improve wear resistance. In many cases, the teeth are then ground again to further refine the profile and ensure extremely tight tolerances.

The process ends with quality control, using 3D measurement instruments and tooth profile verification machines to ensure compliance with the required specifications. Some gears may also undergo protective surface treatments, such as phosphating or nickel plating, depending on the operating environment. All these phases are essential and must be carried out with the highest precision to produce gears that meet the stringent standards required by modern industrial sectors.

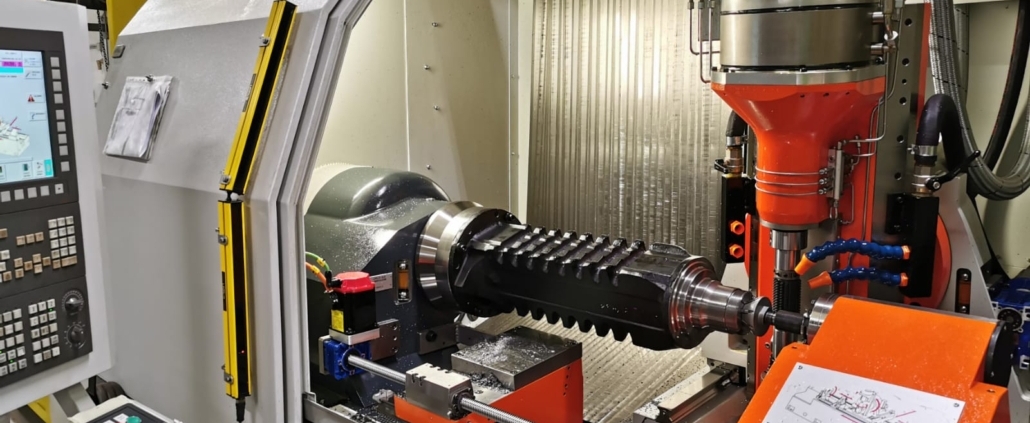

The Impact of CNC Machines on Gear Production

Numerically controlled (CNC) machines have introduced a revolution in gear production, ensuring unprecedented quality thanks to their ability to operate with high precision. These machines, equipped with advanced software, eliminate many of the issues related to human intervention and provide significant advantages, including:

- High precision: They allow for extremely tight tolerances, essential for critical applications such as automotive transmission systems or high-performance industrial machinery.

- Unique flexibility: CNC machines can be easily programmed to produce different types of gears, from standard toothed wheels to more complex geometries.

- Operational efficiency: The automation integrated into CNC machines optimizes the production flow. The machines can operate continuously for extended periods, increasing overall productivity and reducing operating costs.

Robotics and Automation: The Future of Gear Production

The gear industry is undergoing an epochal transformation through the integration of robotics and automation into production processes. Automated production lines allow for consistent processing and production times, and improve component quality by eliminating errors and waste, significantly impacting productivity and the sustainability of processes. Thanks to collaborative robots (cobots), the interaction between humans and machines has become smoother and safer, allowing operators to focus on higher-value tasks, such as design and process optimization.

Collaborative robots can be programmed to perform various operations, such as loading and unloading CNC machines, quality control, and assembly of complex components. An example of their versatility is the IRB 2600 ABB robot used by Ingranaggi Gandini: compact and with high load capacity, its design has been optimized for key applications such as arc welding, material handling, and machine tending. Additionally, advanced robotics allows for the production of gears with increasingly complex geometries and minimal tolerances, improving the final product performance and expanding customization possibilities based on customer specifications.

Another strategic advantage of automation in gear production is the reduction of operational costs. The use of robotic solutions ensures high production standards even in high-demand situations, providing greater flexibility and scalability of production. Finally, the integration of advanced digital technologies, such as in Industry 4.0, can enable the virtual simulation and optimization of production processes before their implementation, reducing costs and waste while increasing company competitiveness in the global market.

Technological Innovations and Sustainability in the Gear Sector

New technologies not only improve production efficiency but can also contribute to promoting environmental sustainability. In a context where environmental respect has become a priority for the manufacturing sector, companies are investing in advanced solutions to minimize waste, optimize resource consumption, and reduce CO₂ emissions.

One of the most notable innovations is additive manufacturing (metal 3D printing), which allows for the creation of lighter and more durable components with a significant reduction in material waste compared to traditional removal methods. This approach not only lowers production costs but also reduces raw material consumption and energy demand, fostering a more sustainable production cycle.

At the same time, energy-efficient machining using the latest-generation CNC machinery helps optimize machining processes, reducing the environmental impact. Additionally, the use of advanced protective treatments on finished products can improve the durability and resistance of gears, reducing the need for replacements and, consequently, the volume of industrial waste.

Another key element of sustainability in the gear sector is the implementation of digital technologies that optimize the design and lifecycle of components. Thanks to the latest technologies, it’s possible to virtually simulate the performance of a gear before production, reducing design errors and the number of prototypes needed, positively impacting waste and consumption reduction.

All of these innovations are contributing to redefine the concept of industrial production, combining high performance with a more responsible approach to the environment.

Ingranaggi Gandini: Technology at the Service of Precision Gear Production

In an increasingly competitive global market, relying on an experienced partner is crucial. Ingranaggi Gandini has specialized in the production of precision gears for over 50 years and has continuously evolved, investing in research and development of new technologies to offer customers advanced solutions, ensure high-quality standards, and meet the demands of a market increasingly focused on component customization.

The company uses the latest-generation CNC machinery, including high-precision machining centers, grinders, slotters, lathes, and advanced gear cutters, as well as involute testers, 3D machines, roughness testers, precision intermeshing gauges, and gear analyzers, ensuring dimensional and geometric checks with the highest precision.

The integration of advanced design software and digital simulations optimizes the design phase, reducing production times and improving the performance of the finished products. Moreover, the use of protective treatments and state-of-the-art superfinituring for the production of Gandini Race crowns and pinions ensures a longer lifespan for gears, making them suitable for high-stress environments such as automotive, aerospace, and industrial mechanics.

Attention to quality is a distinguishing feature of Ingranaggi Gandini, which follows strict production and control standards. Each gear undergoes quality checks and compliance tests to verify dimensional tolerances, roughness, and durability. This level of precision is especially crucial for sectors that require high-performance components that are reliable and long-lasting, such as the motorcycle racing industry.

Contact us to get more information and discover how we can support your business with innovative and efficient gear supply!