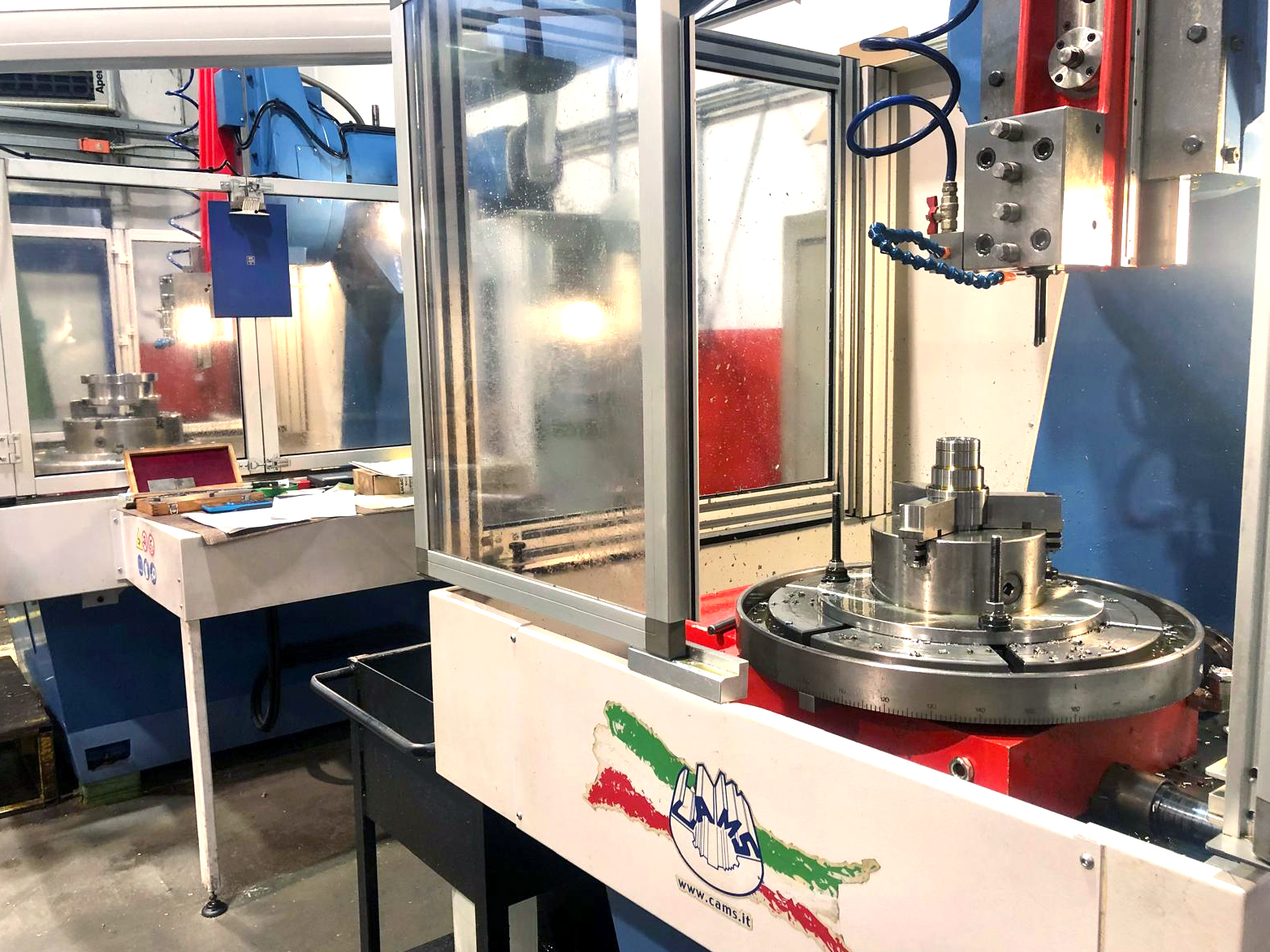

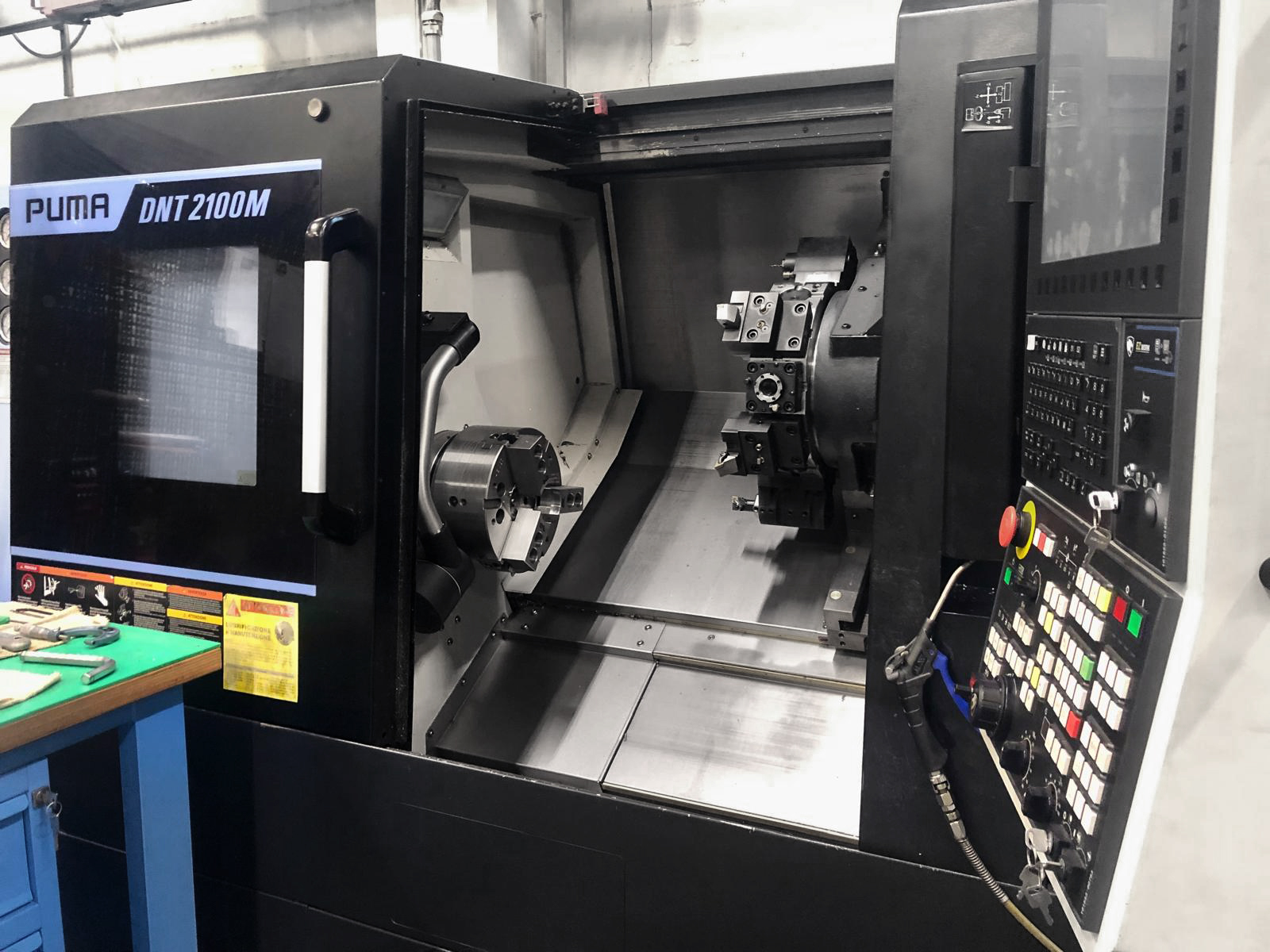

ADVANCED CNC TECHNOLOGY

Our entire machinery fleet is equipped with high-precision CNC machining centers capable of handling complex operations within tight tolerances. By adopting cutting-edge technologies, we can efficiently manage intricate productions while ensuring consistent quality—even in the most critical details. This level of automation allows us to work on a wide variety of geometries and materials, maintaining optimized cycle times and high performance in both prototyping and serial production.